Publish Date: February 26, 2024

LC3-TRC Africa Project Mentored by IIT Delhi Researchers Inaugurated at Kenya’s Meru University of Science and Technology

Share this on

New Delhi: Researchers at IIT Delhi have been playing a leading role in bringing Limestone Calcined Clay Cement (LC3), a more sustainable cement with higher performance, to the market in India and internationally. As a part of its commitment to global scientific outreach, an LC3-Technology Resource Centre (TRC) Africa Project at Kenya’s Meru University of Science and Technology has been set up under the mentorship of IIT Delhi.

The project was jointly inaugurated by IIT Delhi’s Prof. Shashank Bishnoi and Prof. Karen Scrivener, EPFL, Switzerland, on February 14, 2024.

The LC3-TRC Africa is an important addition, as it will help in the sustainable development of Africa and build capacity in the area of cement research there. The LC3-TRC Africa will strive to facilitate the adoption of LC3 technology within the construction sector across Sub-Saharan Africa by fostering collaboration among industry holders, innovators, and policymakers. It will also offer consulting services and support for LC3 usage.

To cater to the demand to provide knowledge and information in African countries, IIT Delhi has collaborated with Meru University to open a laboratory to support the African cement and construction industry. “Along with supporting the need for the global cement industry to grow in a sustainable manner, LC3 promises to make cement more affordable for development in Africa,” Prof. Shashank Bishnoi said.

LC3 is a family of composite cements containing clinker, calcined clay, and limestone that was developed at EPFL, Switzerland, in collaboration with UCLV Cuba. Researchers at IIT Delhi, led by Prof. Shashank Bishnoi from the Civil Engineering Department, contributed the largest volume of research that has brought cement from the laboratory to the market.

In India, research on LC3 started in 2012, and the Bureau of Indian Standards (BIS) published the standard for LC3 (IS18189) in June 2023 to make the technology ready to be used by the cement industry in the country. BIS allows the production of LC3 with 50% clinker, the remaining being calcined clay (usually around 30%) and crushed limestone (usually around 15%).

The LC3 technology promises sustainable growth for economies around the world by reducing CO2 emissions by more than 40% compared to plain Portland cement at lower production costs. LC3 is strong, durable, and can be used in the same manner as other cements.

Due to the lower clinker content, the LC3 technology has following advantages over Ordinary Portland Cement (OPC) and Portland Pozzolanic Cement (PPC):

a) Improved resource efficiency

b) Lower CO2 emission per tonne of cement produced

c) Reduced production cost without compromising the performance of the cement

d) Easy processing and supported by existing production facilities hence low capital investment costs

e) Almost double the cement output per tonne of clinker

f) Enhanced durability of building materials and concrete produced using LC3

ENDS

Other News

Indian Navy’s Directorate of Naval Architecture Signs MoU with IIT Delhi for Crew Centred Aspects of Warship Design

Read More

Online CEP programme in "Executive Management Programme in Entrepreneurship Development ( Batch 4)"

Read More

IIT Delhi and Samco Inc., Japan, Join Hands to Boost Semiconductor and High-Efficiency Silicon Solar Cell Research

Read More

Online CEP programme in "Executive Programme for Advanced Product Management ( Batch 04 )"

Read More

Online CEP programme in "Executive Programme in Semiconductor Manufacturing and Technology (Batch 2)"

Read More

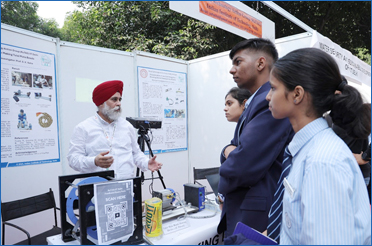

IHFC, the TIH of IIT Delhi, Showcases 25 Cutting-Edge Technologies to Mark its 5th Anniversary

Read More

Adi Karmayogi Student Chapters Launched at IITs, IIMs, AIIMS, NITs and Top Institutions – Empowering Tribal Youth as Leaders, Innovators, and Change-Makers

Read More

Online CEP programme in "Certificate Programme in Data Science and Machine Learning ( Batch - 11)"

Read More

Online CEP programme in "Certification in Quantum Computing and Machine Learning (Batch 07)"

Read More

Shri Dharmendra Pradhan, Minister of Education, Inaugurates Key Programs and Startup Incubator at IIT Delhi - Abu Dhabi, Reinforcing a Landmark Bilateral Partnership

Read More

SAI NCSSR and IIT Delhi Sign MoU to Give Impetus to Wider Use of Sports Science and Innovation in India

Read More

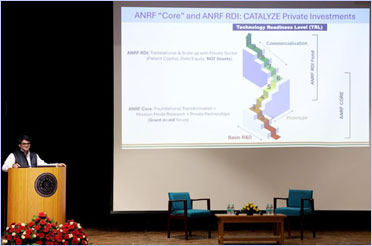

CEO of ANRF Delivers an Insightful Institute Lecture titled “ANRF Vision: Catalyzing India’s Rise as a Research and Innovation Powerhouse” at IIT Delhi

Read More

IIT Delhi Inaugurates Biosafety Level 3 Research Facility to Foster Research Involving Highly Infectious Pathogens

Read More

IIT Delhi and Wadhwani Foundation Inaugurate Centre of Excellence in Precision & Personalized Healthcare under Wadhwani Innovation Network

Read More

Union Minister of Textiles Launches Report on Handloom Carbon Footprint Assessment Prepared by IIT Delhi and DC (Handlooms)

Read More

Online CEP programme in "Certificate Programme for Future Tech Leaders AI & Industry 5.0 (Batch 1)"

Read More

56th Convocation: 2764 IIT Delhi Students Awarded Degrees and Diplomas; Chief Guest Dr. Tessy Thomas, the Missile Woman of India, Inspires Graduating Students

Read More

IIT Delhi to Hold 56th Convocation on August 2, 2025; the Missile Woman of India, Dr. Tessy Thomas, to be the Chief Guest

Read More

Online CEP programme in "Artificial Intelligence and Machine Learning for Industry (Batch 6)".

Read More

Online PG Diploma programme in "Online PG Diploma In Healthcare Product Development And Management".

Read More

Online PG Diploma programme in "Online PG Diploma In Advanced Communication Engineering With Quantum And AI Integration".

Read More

Online CEP programme in "Executive Programme In Operations Management And Analytics (Batch - 6 )".

Read More

Online CEP programme in "Executive Programme In Generative AI And Next Gen Digital Engineering (Batch 1 )".

Read More

Online CEP programme in "Advanced Certificate Programme In AI, ML And DL ( Formerly Known As Certificate Programme In Machine Learning And Deep Learning )".

Read More

Online CEP programme in "Applied Data Science And Artificial Intelligence: From Fundamentals To Deployment - Batch 02".

Read More

Online CEP programme in "Executive Programme In Augmented Reality & Virtual Reality (Batch - 2 )".

Read More

Workshop on ‘Future Ready Energy Education: Opportunities and Challenges’ Held at IIT Delhi

Read More

Change Makers 2025 Summer Bootcamp Successfully Culminates at IIT Delhi with High School and 1st Year UG Students Presenting Promising Innovative Solutions to Environmental Challenges

Read More

QS World University Rankings 2026: IIT Delhi Features in List of Top 125 World Institutions; Emerges as No. 1 Educational Institute in India

Read More

IIT Delhi and LG Electronics Partner to Drive Innovation in Sustainable Home Appliance Technologies

Read More

World Environment Day 2025 Celebrated at IIT Delhi; Institute Highlights Need for Collective Action

Read More

IIT Delhi to Organise Open House in Delhi, Mumbai and Bengaluru for JEE Advanced 2025 Qualified Candidates

Read More

IIT Delhi launches new undergraduate programme BS in Chemistry for JEE (Advanced) 2025 qualified candidates

Read More

Central Electricity Regulatory Commission, IIT Delhi and Grid Controller of India sign MoU to Establish Centre of Excellence for Regulatory Affairs in Power Sector

Read More

Provisional Waiting List of Candidates for the Ph.D. Program in Materials Science and Engineering

Read More

HORIBA India Join Hands with IIT Delhi to Support Three Technical Development Research Projects

Read More

Provisional *List of Selected Candidates for Ph.D. in Materials Science and Engineering, *Subject to Document Verification by the Academic Section DMSE

Read More

IIT Delhi Hosts ‘Manasvi: STEM Mentorship Program for High School Girls’ – Empowering Young Girls with Exposure and Opportunities to Become Future-Ready for STEM

Read More

IIT Delhi Debuts Online Post Graduate Diplomas to Empower Next-Gen Technological Leadership

Read More

Manufacturing Innovation Show: Agricultural Machineries, On-road Power Generation Device Among Several Prototypes Developed by 1st Year IIT Delhi UG Students

Read More

IIT Delhi Establishes a Chair on Applied AI for Sustainable Systems in Collaboration with R Systems

Read More

Fuelling a Sustainable Future: IIT Delhi-Abu Dhabi Announces Second Intake for Post-Graduate Energy & Sustainability Programs

Read More

IIT Delhi Successfully Conducts CAIC Student Elections Through E-Voting, Eyes Scaling to Larger Platforms

Read More

Shortlisted candidates list & shortlisting Criteria for PhD admission in Textile department

Read More

Shortlisted candidates list & shortlisting Criteria for MTech admission in Textile department

Read More

IIT Delhi, Central Water Commission Sign MoU for Water Resources Management Through Data Science, AI and Machine Learning

Read More

IIT Delhi Celebrates the Legacy of Dr. B.R. Ambedkar with “Jai Bhim Saptah” – A Week of Reflection, Dialogue, and Action

Read More

Placement 2024-25: UG Students at IIT Delhi Secure 850 Unique Offers to Date, Highest in Last Three Years

Read More

Bhagwan Birsa Munda Cell at IIT Delhi Hosts Tribal Students and Youth for an Exposure Visit

Read More

Empowering the Future: Through NURTURE Program IHFC (TIH of IIT Delhi) Trains Over 50,000 SC/ST Students in Cutting-Edge Technologies

Read More

Online CEP programme in "Certificate Programme in Machine Learning and Deep Learning (Batch 6)."

Read More

Online CEP programme in "Advance Programme in Electric Vehicle (EV) Technology (Batch 8)."

Read More

Quantum Materials & Devices (QMD) Hub at IIT Delhi Successfully Hosts its Grand Inception & Strategy Summit

Read More

Online CEP programme in "Certificate Programme in Data Science & Machine Learning(Batch 10)"

Read More

Online CEP programme in "Artificial Intelligence and Machine Learning for Industry (Batch 05)"

Read More

IIT Delhi Invites Applications from High Schoolers and 1st Year UG Students for Change Makers 2025 Summer Bootcamp

Read More

JAM Admission Portal JOAPS for Various Master’s Programs in IITs to Open from March 26, 2025

Read More

IIT Delhi organises ‘Anveshan 2025’ as a part of the Institute’s initiative of “Experience IITD”

Read More

International Happiness Day Celebration marks the inauguration of Rekhi Mind Lab at IIT Delhi to promote Happiness Studies

Read More

Online CEP programme in "Certificate Programme in Hybrid Electric Vehicles (HEVs) Design (Batch 2) "

Read More

Online CEP programme in "Advanced Certification in Data Science and Decision Science (Batch 5) "

Read More

New Zealand Prime Minister Strengthens Academic Ties with India, Announces Scholarships at IIT Delhi

Read More

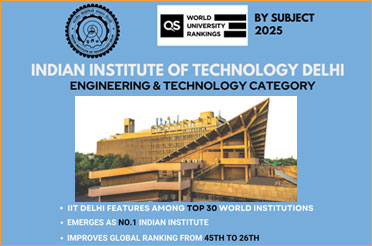

QS World University Rankings by Subject 2025: IIT Delhi Features Among Top 30 World Institutions in Engineering & Technology Category

Read More

IIT Delhi to Organise an Insightful Event, “Anveshan: Innovation and Exploration Across Disciplines”, for Undergraduate and Postgraduate Students, Showcasing Curriculum, Research, and Campus Life

Read More

SANGAM, An Inclusive Intercollege Sports Event for Students with Disabilities, Held at IIT Delhi

Read More

Inaugural Chidambaram Memorial Lecture held at IIT Delhi on National Science Day; Prof Abhay Karandikar, DST Secretary, Delivered the Inaugural Lecture

Read More

Bhagwan Birsa Munda Cell at IIT Delhi Hosts an Exposure Visit for 200 Tribal Students from Five States

Read More

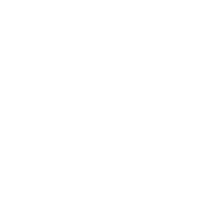

Opportunity to work on the UQ - IITD Research Academy and Weir IP Group Ltd., Scotland supported project

Read More

IIT Delhi Opens Its Doors to Teachers from Technical Institutions in Haryana for Skill Enhancement and Research-Driven Learning

Read More

IIT Delhi, IndiGo Sign MoU to Drive Innovation and Create Impactful Solutions for Airline Industry

Read More

College Youth Ideathon 2025: An initiative to Fuel Innovation and Entrepreneurship Among India’s Youth Launched by IIT Delhi, MEPSC, and ThinkStartup

Read More

IIT Delhi and University of Exeter, UK, Host Joint Symposium on Sports Healthcare Science and Engineering

Read More

2nd Transformative Leadership in STEMM (TLS) Workshop for Ph.D. Scholars from SC/ST Community Held at IIT Delhi

Read More

IHFC Collaborates with 10 Leading Institutions Across India to Launch Transformative Co-Innovation Centres (CiC) in Deep Tech, AI and Robotics

Read More

150 High School Students Attend Inaugural Lecture Under “Sci-Tech Spins” Lecture Series 2025 at IIT Delhi

Read More

Online CEP programme "Certificate Programme in Applied Data Science & Artificial Intelligence: From Fundamentals to Deployment"

Read More

CEP programme "One-week Training Programme on Construction Quality Control and Management"

Read More

Swami Vivekananda Jayanti at IIT Delhi: Experts talk on Vedanta, Leadership, and India's Educational Legacy

Read More

NISHAAN 2025, a Cultural Event Celebrating Diversity and Talent of Students with Disabilities, Organised at IIT Delhi

Read More

Third Batch of IIT Delhi’s STEM Mentorship Program for High School Girls Successfully Concludes

Read More

IIT Delhi Hosts Mr. Amandeep Singh Gill, UN Under-Secretary-General for Digital and Emerging Technologies and Secretary-General's Envoy on Technology, For a Discussion on AI Governance

Read More

Jake Sullivan, USA’s National Security Advisor, Delivers a Talk on 'The United States and India: Building a Shared Future' at IIT Delhi

Read More

TRIP Centre, IIT Delhi, organizes a roundtable discussion on “Gendered Resilience in Transport: Enhancing Adaptation to Extreme Heat in Delhi”

Read More

DRDO Industry Academia-Center of Excellence (DIA-CoE) at IIT Delhi Transfers Technology of ABHED, a Light Weight Bulletproof Jacket, to three Indian Industries

Read More

CEP programme on "Certificate Programme in Industrial Polymer Production: Combined Chemistry and Chemical Engineering Approaches"

Read More

IIT Delhi Students Are Choosing Diverse Career Paths, Shows the Graduation Exit Survey 2024

Read More

DFPD Launches ‘Anna Chakra’ PDS Supply Chain Optimization Tool Developed by PSL, IIT Delhi

Read More

IIT Delhi Leads Landmark Collaboration with Hyundai Motor Group to Advance Battery and Electrification Research

Read More

3rd online CEP programme on "Executive Programme in Healthcare Entrepreneurship and Management"

Read More

Bhagwan Birsa Munda Cell at IIT Delhi Hosts Commemoratives Events on Janjatiya Gaurav Diwas

Read More

AIIMS New Delhi, IIT Delhi and UCL Announce Trilateral Partnership to Scale Up MedTech Innovation

Read More

Call for Applications: Transformative Leadership in STEMM (TLS) Workshop for Advanced PhD Scholars from SC/ST community.

Read More

IIT Delhi and Centre for Railway Information Systems Partner to Transform Indian Railways Through Cutting-Edge Research

Read More

AI to Empower, Not Threaten: Meta's Chief AI Scientist Yann LeCun Calls for New Model Architectures at IIT Delhi

Read More

IIT Delhi Launches MS (Research) Program in ‘Healthcare Technology’ for Medical and Allied Clinical Professionals

Read More

Workshops Organised for Parents and School Kids to Raise Awareness and Co-Create Possible Solutions to Beat the Heat

Read More

Joint Report by IIT Delhi and IEA: "Clean Energy Innovation Policies in Emerging and Developing Economies"

Read More

PGDEx-VLFM Batch 07 Students Meet IIT Delhi Director; Witness an Inspiring Interactive Session

Read More

IIT Delhi, IAF Join Hands for AI-powered Research on Technical Textiles; to Focus on Parachute and Other Safety Equipment

Read More

4th online CEP programme "Executive Management Programme in Supply Chain & Operations Analytics"

Read More

India's first-of-its-kind DST Supported CO2-to-Methanol Pilot Plant Project to be Implemented by IIT Delhi and Thermax Ltd. in PPP Mode

Read More

Major Milestones for IIT Delhi as His Highness Sheikh Khaled bin Mohamed Visits Abu Dhabi Campus

Read More

IIT Delhi and Systra Group Sign MoU to Collaborate on Research Advancing Sustainable Development Goals

Read More

Joint Admission Test for Masters (JAM) 2025: Application window opens on 3rd September 2024

Read More

Materials Science and Engineering Dept. at IIT Delhi Hosts Training Program on ‘Polymer Science and Technology’ for IOCL Executives

Read More

Rashtriya Vigyan Puraskar 2024: Prof. Bhim Singh, SERB National Science Chair and Emeritus Professor at IIT Delhi, Honored with the Vigyan Shri Award

Read More

CEP programme "Workshop on Enabling Renewable Energy Integration in Modern Power Systems with Advanced Technologies"

Read More

IIT Delhi Honors Alumni with Prestigious Distinguished Alumni Awards 2024 at 55th Convocation Ceremony

Read More

IIT Delhi to Hold its 55th Convocation on August 10, 2024; Shri. Hari S. Bhartia, Founder and Co-Chairman, Jubilant Bhartia Group to be Chief Guest

Read More

Important Information for PhD students regarding seating of Guests in Dogra Hall in 1st Phase

Read More

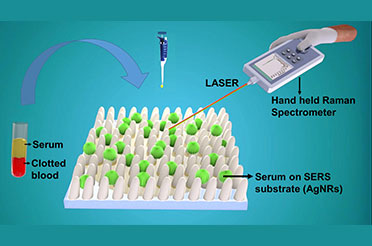

IIT Delhi Develops Two Pioneering Healthcare Technologies; Successfully Transfers them to Industry

Read More

DD Robocon India 2024: Nirma University from Gujarat Wins Robotics Competition; Maharashtra’s Pimpri Chinchwad College of Engineering Secures Runner-up Position

Read More

Initiative for Gender Equity and Sensitisation (IGES) at IIT Delhi to Organise Wikipedia Edit-a-Thon on July 5

Read More

Bridging the Gap: IIT Delhi’s Aab Prahari App Enables Citizens to Report Real-Time Flooding Incidents and Help Civic Agencies During Monsoon

Read More

An Open House for All JEE (Advanced) 2024-Qualified Candidates Aspiring to Join IIT Delhi’s Hauz Khas Campus in India or Abu Dhabi Campus in UAE to be Organised on June 15, 2024

Read More

Students Clearing JEE Advanced 2024 can apply for Admissions to IIT Delhi-Abu Dhabi Campus

Read More

UQ-IITD Research Academy - Promotion of the Call for Collaborative Research grant applications

Read More

Entrepreneurship Development Cell at IIT Delhi Collaborates with Alumni to Conduct an Entrepreneurship Course for Students on Building Successful Startups from Scratch

Read More

IIT Delhi’s Technology Innovation Hub IHFC, ITU Collaborate to Organise ‘Robotics for Good Youth Challenge’

Read More

2nd online CEP programme on "Executive Programme in Product Innovation and Design Thinking for Business Growth".

Read More

SUMMER RESEARCH FELLOWSHIP PROGRAMME 2024 FOR M.TECH. /M.E. STUDENTS AT INDIAN INSTITUTE OF TECHNOLOGY DELHI

Read More

QS World University Rankings by Subject 2024: IIT Delhi Ranked Among the Top 100 World Institutions in 08 Specific Subject Areas; Features Among Top 50 in Engineering and Technology

Read More

International Women's Day: Talk titled "Rise to Shine: Embracing Challenges for Success” Organised

Read More

Antara Senior Care Signs MoU with IIT Delhi to Design Innovative Mobility-aid Solutions for Seniors

Read More

Israel Aerospace Industries and IIT Delhi Sign CSR Agreement to Collaborate on Applied Research

Read More

IIT Delhi’s Department of Humanities and Social Sciences to Offer a New Academic Program ‘M.A. in Culture, Society, Thought’

Read More

Completion of Sequencing of 10000 Genomes of Indian Population: IIT Delhi Scientists Make Significant Contribution

Read More

Bill Gates Inspires IIT Delhi Students, Encourages Them to Apply Their Skills to Global Challenges

Read More

03rd online CEP programme titled "Executive Management Programme in Advanced Strategic Management"

Read More

R Systems International Ltd. and IIT Delhi Partner to Set Up a Centre of Excellence on Applied AI for Sustainable Systems

Read More

Transformative Leadership in STEMM (TLS) Workshop for Ph.D. Scholars from SC/ST Community Held at IIT Delhi

Read More

IIT Delhi Launches a New Academic Program ‘M.Sc. in Biological Sciences’; Admissions Through JAM

Read More

GRIP: IIT Delhi Students Visit Uttarakhand Villages; Will Develop Tech Solutions to Address Issues Faced by Local Population

Read More

National Service Scheme (NSS) of IIT Delhi Launches an In-house-developed Mobile App, Making Volunteering Much More Accessible

Read More

Call for Applications: Transformative Leadership in STEMM (TLS) Workshop for Advanced PhD Scholars from SC/ST community.

Read More

Request for Proposal: Empanelment of Service providers for the Online CEP Programmes at IIT Delhi

Read More

2nd online CEP programme titled "Executive Programme in Healthcare Entrepreneurship and Management"

Read More

Consultative Brainstorming Meeting: ‘DST's Roadmap Towards India’s Net Zero Targets Through Carbon Capture, Utilization, and Storage’

Read More

04th online CEP programme titled "Certification in Quantum Computing and Machine Learning"

Read More

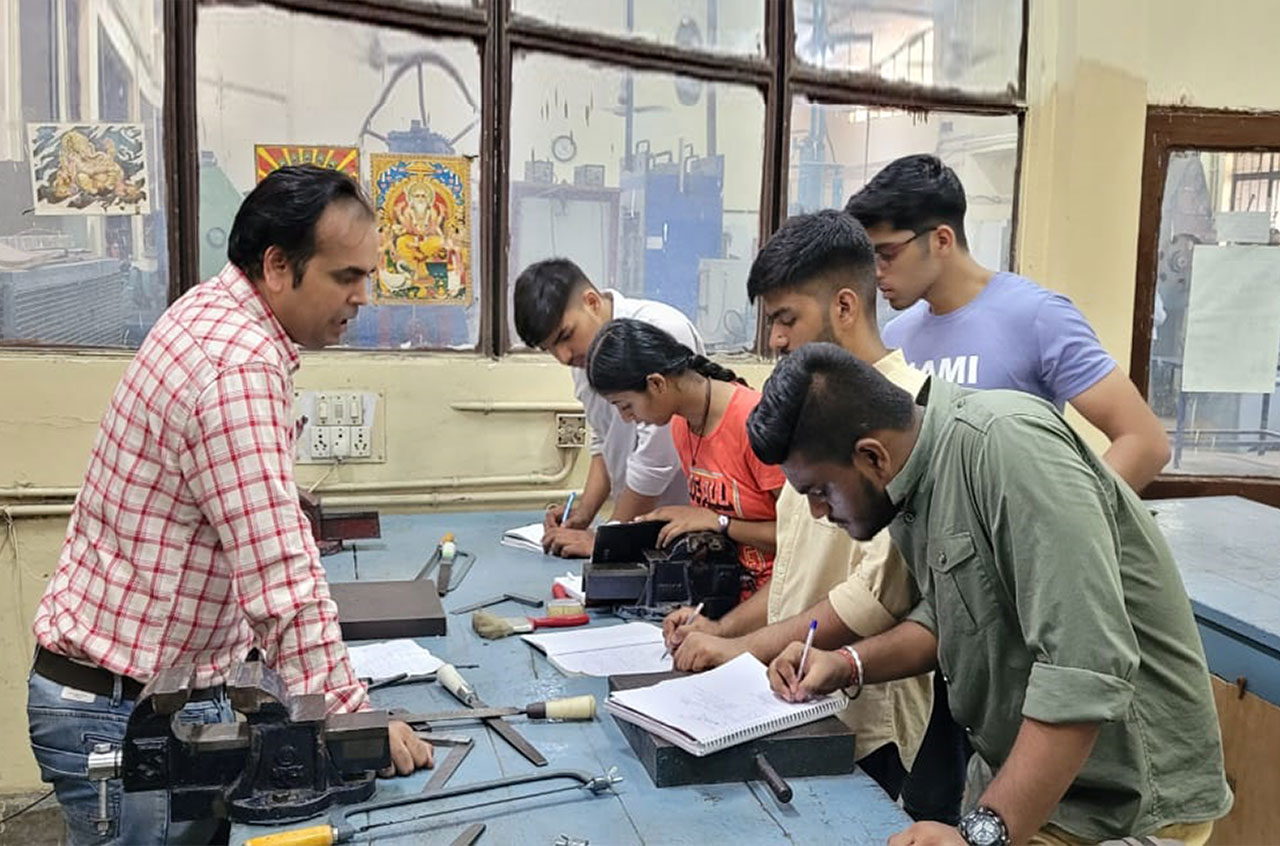

IIT Delhi Faculty Combines Technology with Art Forms to Offer a Holistic Educational Experience to Materials Engineering Students

Read More

Placement Season Begins at IIT Delhi- Students Receive 480 Job Offers By the End of December 1

Read More

Over 30 High School Girls Successfully Complete Second STEM Mentorship Program Launched by IIT Delhi

Read More

BioTEX-2023 : Organized by the CBME, Indian Institute of Technology (IIT) Delhi at New Delhi from 27th November-1st December 2023

Read More

Shortlisting Criteria and List of candidates shortlisted for interview for the MSR Program in the Department of Materials Science and Engineering for the session 2023-24, II Semester

Read More

Short-listing criteria for admission to Ph.D. in Materials Science and Engineering for the year 2023-2024 (2nd Semester)

Read More

IIT DELHI ANNOUNCES M. TECH. IN ENERGY TRANSITION AND SUSTAINABILITY FOR THE ABU DHABI CAMPUS: Last date extended to November 30, 2023

Read More

3rd online CEP programme titled "Advanced Certification in Data Science and Decision Science"

Read More

online CEP programme titled "Hands-on Training on "Semiconductor Device Technology: Fabrication and Characterization"

Read More

IIT Delhi Faculty Prof. Shilpi Sharma and Prof. Anurag Singh Rathore Win Tata Transformation Prize; Recognized for their Cutting-Edge Solutions to Food Security and Healthcare

Read More

Hon'ble Vice-President of India, Shri Jagdeep Dhankhar, Visits IIT Delhi and Interacts with Students

Read More

In pictures: Hon'ble Vice-President of India, Shri Jagdeep Dhankhar, Visits IIT Delhi and Interacts with Students

Read More

Tehri Hydro Development Corporation India Limited (THDCIL) and IIT Delhi Ink MoU for Transformative Research and Development Initiatives

Read More

DAKSH Centre of Excellence for Law and Technology at IIT Delhi Launches a Book Titled ‘Technology and Analytics for Law and Justice’

Read More

IIT Delhi and HORIBA India Jointly Hold Tech Symposium on ‘Solutions for Semiconductor Industry’

Read More

In pictures: Birth Anniversary of Mahatma Gandhi and Shri Lal Bahadur Shastri Celebrated at IIT Delhi

Read More

First of Its Kind ‘Medical Cobotics Centre (MCC)’ Inaugurated in New Delhi; to Foster Innovation in Healthcare

Read More

online CEP programme titled "Certificate Programme in Project Management: Theory & Practice"

Read More

IIT Delhi’s Prof. Dipti Ranjan Sahoo Wins Shanti Swarup Bhatnagar Prize for Science and Technology 2022

Read More

IIT Delhi and EXL Enter into MoU to Work Towards Empowering Women Entrepreneurs Through Digital and Financial Literacy

Read More

2nd online CEP programme titled "Executive Management Programme in Advanced Strategic Management"

Read More

First Batch of UQIDAR Students Receive Joint PhD Degree at 54th IIT Delhi Convocation Ceremony

Read More

In pictures: IIT Delhi Celebrates Independence Day; Employees Awarded for Exemplary Contribution to Institute

Read More

IIT Delhi's School of Public Policy Successfully Places its Inaugural Masters in Public Policy Batch

Read More

Workshop on MedTech and Healthcare Ecosystem for Upcoming IIT Delhi - Jhajjar Campus Organised

Read More

2357 Graduating IIT Delhi Students Receive Degrees and Diplomas at the 54th Annual Convocation Ceremony

Read More

IIT Delhi to Hold its 54th Convocation on August 12; Eminent Virologist Dr. Gagandeep Kang to be the Chief Guest

Read More

IIT Delhi Successfully Organizes Open House for JEE (Advanced) 2023 Qualified Female and PwD Candidates

Read More

IIT Delhi Research Scholar Anchal Sharma Makes Research Presentation Before Indian PM and US First Lady at NSF

Read More

IIT Delhi is organising an Open House for JEE (Advanced) 2023 qualified Female and Pwd Candidates on June 24, 2023 (Saturday)

Read More

online CEP programme titled "Applied Data Science using Machine Learning & Artificial Intelligence"

Read More

IIT Delhi Celebrates World Telecommunication Day; India’s G20 Sherpa, Mr. Amitabh Kant, Delivers Annual Bharti Lecture

Read More

RESULT OF SUMMER RESEARCH FELLOWSHIP PROGRAMME -2023 WILL BE DECLARED BY THE SECOND WEEK OF MAY, 2023

Read More

MechAnalyzer Software to Help Engineering Students Learn Concepts of Mechanisms; FITT-IIT Delhi and SVR InfoTech Sign MoU for Sale and Tech Support

Read More

Venus Chair Established at IIT Delhi to Support Teaching and Research & Development in the Area of Fibrous Air Filters

Read More

Deadline of Submission of Online Applications for SRFP - 2023 extended upto 19.04.2023 till 11:59 PM

Read More

2nd online CEP programme titled "Advanced Certification in Data Science and Decision Science (Batch 2) "

Read More

IIT Delhi’s Two-Day Annual Career Fest ‘Pravritti 2023- Expanding Horizons’ to Begin on April

Read More

2nd online CEP programme titled "Executive Programme for Advanced Product Management (Batch 2)"

Read More

online CEP programme titled "Executive Programme in Product Innovation & Design Thinking for Business Growth"

Read More

QS World University Rankings by Subject 2023: IIT Delhi Among the Top 50 Institutions in the World in Engineering & Technology with 48th Rank

Read More

MoS for Education Dr. Subhas Sarkar Inaugurates Unnat Bharat Abhiyan's "UNNATI Mahotsav and Expo" at IIT Delhi

Read More

In pictures- Hon'ble Australian PM Mr. Anthony Albanese's Visit to IIT Delhi on March 10, 2023

Read More

Hon’ble Australian Prime Minister Mr. Anthony Albanese Visits IIT Delhi; Addresses Students

Read More

IIT Delhi’s Three-day Annual Science, Technology and Management Festival “Tryst 2023” Kicks Off

Read More

IIT Delhi Alumnus Alok Aggarwal Endows Chair for Research in ESG (Environmental, Social, and Governance) Area

Read More

IIT Delhi to Develop Smart Monitoring System to Ensure Safety of Persons Working at Height

Read More

65th Foundation Day of IIT Delhi Celebrated; Faculty Research Awards 2022 Presented on Foundation Day

Read More

Mobility for All: Continental with IIT Delhi Develop A Solution for Visually Impaired To Access Public Buses

Read More

27th Inter-IIT Staff Sports Meet: IIT Delhi Wins Overall Championship and General Championship (Men)

Read More

IIT Delhi Placement Drive 2022-23: Students Receive Record Number of Job Offers Up to December 15

Read More

IIT Delhi and University of Helsinki, Finland, Sign MoU for Academic Cooperation; Aims to Contribute to Solving Air Quality and Climate Change Challenges in India

Read More

CRDT, IIT Delhi Organises International Symposium on Circular Economy Solutions for Plastics and Microplastics jointly with University of Eastern Finland (UEF)

Read More

Four Startups led by IIT Delhi Students Win a Grant of Rs 50 lakh Each Under Endowment Nurture Fund Initiative

Read More

Advertisement inviting applications for the post of Director, IIT IIT Kanpur and IIT (ISM) Dhanbad

Read More

IIT Delhi Holds 53rd Annual Convocation Ceremony; 2100 Graduating Students Awarded Degrees and Diplomas

Read More

Rural Technology Action Group (RuTAG) at IIT Delhi Transfers Two Technologies to Four African Nations

Read More

Department of Telecommunications R&D Centre C-DOT and IIT Delhi Sign MoU for Cooperation in Various Emerging Areas of Telecom

Read More

Workshop on Addressing Air Quality Challenges in Delhi-NCT Held at IIT Delhi; Team Sweden, IIT Delhi Identify Possible Areas of Joint Intervention

Read More

Supreme Court Judge Hon’ble Justice D.Y. Chandrachud to Deliver Inaugural Talk for the Office of Diversity and Inclusion at IIT Delhi

Read More

Hon’ble Union Education Minister, Shri Dharmendra Pradhan Addresses IIT Delhi Diamond Jubilee Celebrations Closing Ceremony

Read More

IIT Delhi Diamond Jubilee Celebrations Closing Ceremony- Director Prof. Rangan Banerjee's Speech

Read More

IIT Delhi Diamond Jubilee Celebrations Closing Ceremony- Hon'ble President of India, Smt. Droupadi Murmu's Speech

Read More

Hon’ble President of India, Smt. Droupadi Murmu Graces IIT Delhi Diamond Jubilee Celebrations Closing Ceremony

Read More

FSAE Italy 2022- IIT Delhi’s Automobile Club AXLR8R Formula Racing Secures First Position in Cost and Manufacturing Event

Read More

Union Minister Shri Piyush Goyal Inaugurates Public Systems Lab at IIT Delhi Established in Partnership with UNWFP

Read More

IIT Delhi’s Technology Innovation Hub IHFC Gets 12 Projects Under DST-NSF Joint Research and Development Program

Read More_1659327288.jpg)

IIT Delhi Organises Academic Outreach Day for Students and Faculty of Haryana Govt. Technical Universities and Colleges

Read More

NIRF India Rankings 2022- IIT Delhi Achieves 2nd Rank in Engineering; Jumps to 4th in Management; Features Among Top 3 Research Institutes

Read More

mPRAGATI, a One Stop MedTech Technology Development Facility at IIT Delhi Under ICMR-Medical Device and Diagnostics Mission Secretariat, Unveiled

Read More

Empanelment of retired officers as an Inquiry Officers for conducting Departmental Inquiry - reg.

Read More

First Batch Successfully Completes IIT Delhi’s STEM Mentorship Program for High Schoolgirls

Read More

School students showcase promising prototypes they built at Change.Makers summer boot camp organised by IIT Delhi

Read More

IITs in Delhi, Bombay and Kanpur Offer Internship and Sponsored M. Tech. Programmes to Students from Ladakh

Read More

IHFC, TIH of IIT Delhi, Celebrates its 2nd Anniversary; Announces Call for Proposal in Areas of Autonomous Vehicles, Nano Robotics, Block Chain for Applications in Robotics

Read More

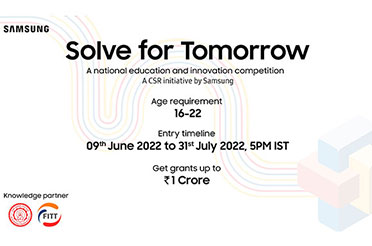

Samsung Launches ‘Solve for Tomorrow’, an Innovation Contest for India’s Youth to Crack Real-World Problems; FITT at IIT Delhi to be the Knowledge Partner

Read More

QS World University Rankings 2023- IIT Delhi Achieves an Improved Overall Rank of 174 Globally

Read More

DEPARTMENT OF HUMANITIES AND SOCIAL SCIENCES, IIT DELHI --- Indian & Foreign Languages Learning Programme

Read More

Result- UG - Summer Research Fellowship Programme - 2022 ( IN CONTINUATION TO THE LIST OF STUDENTS PUBLISHED on 13th May, 2022 )

Read More

Technology Innovation Hub of IIT Delhi (IHFC) Signs MoU with the Council for the Indian School Certificate Examinations (CISCE)

Read More

Did Climate Change Cause Ancient Civilizations to Collapse? 08thIIT Delhi SciTech Spins Lecture to Explain

Read More

PG Admission including Ph.D. - Last date for submission of online application and application fee has been extended to April 17, 2022 (4 pm). No further extension will be made.

Read More

QS World University Rankings by Subject 2022 - Five IIT Delhi Academic Programmes in Top 100

Read More

IIT Delhi, Delhi Jal Board Sign MoU to Address Water Security Issues Faced by NCT of Delhi

Read More

World Class Indoor Sports Complex Built with Alumnus Saurabh Mittal's Support Inaugurated at IIT Delhi

Read More

2nd online CEP Certificate programme titled Executive Management Programme in Entrepreneurship Development (EMPED)

Read More

Fabiosys Innovations, an IIT Delhi Startup, Develops Technology to Manufacture Extremely Affordable and Highly Effective Antiviral Fabric

Read MoreCOVID-related Research & Development Work by Centrally Funded Technical Institutes (CFTIs), Ministry of Education, Government of India - February 2022

Read More

IHFC, Technology Innovation Hub of IIT Delhi, Collaborates with US’ National Science Foundation for Research in Cobotics, AI

Read More

Webinar on "What's next in computing: when classical and quantum computing meet" by Dr. Mukesh V. Khare, Vice President, Semiconductor & Cloud, IBM Research, USA on March 04 (Friday) 2022, 8:30 AM IST

Read More

HORIBA India, IIT Delhi Join Hands to Establish Research Center at the Institute’s Chemistry Department

Read More

Troop Comforts Ltd Signs MoU with IIT Delhi to Develop Smart Protective Clothing for Indian Security Forces

Read More

SciTech Spins Lecture: School Students to Learn About Role of Imaging in Advancing Science and Technology

Read More

IIT Delhi Launches an Interactive Website of IIT-PAL to Help High School Students Prepare for Competitive Exams

Read More

IIT Delhi Researchers Develop High Efficiency, Shadow-less, Portable Solar PV Towers for Power Generation

Read More

IIT Delhi Sets up “Pillay Chair Professor” for Research in Machine Learning, VLSI Design and Sensors

Read More

IIT Delhi Students Receive Record Number of Job Offers Up to December 15 of Placement Drive 2021

Read More

SciTech Spins 4th Lecture: School Students to Learn About Mysteries of Universe from IIT Delhi Scientists

Read More

IIT Delhi’s State of the Art Research & Innovation Park Wins Prestigious Façade Project of the Year Award 2021

Read More

Brain Storming Conclave on Atmanirbhar North East through S&T Interventions at Cotton University, Guwahati, Assam December 21–22, 2021

Read More

IntelliSmart & IIT Delhi collaborate to develop next generation Smart Grid technology solutions & capabilities

Read More

IIT Delhi Collaborates with National Law University Delhi for Ushering in Tech-empowered Justice System

Read More

IIT Delhi and Business Sweden - The Swedish Trade and Invest Council Sign MoU for Clean Air and Green Energy Collaborations

Read More

Neilom Prize 2020-21: Recent Graduates of IIT Delhi Awarded for their Work in the Field of Assistive Technology

Read More

‘Why did the Titanic Sink?’ 3rd SciTech Spins Lecture by IIT Delhi to Explain This and Many More Questions to School Students

Read More

Technology Innovation Hubs of IIT Delhi and IIIT Delhi Sign MoU to set up India’s First Medical Cobotics Centre

Read More

State-of-the-art Laboratories Inaugurated at IIT Delhi’s Centre Focusing on Electric Vehicle Technologies

Read More

IIT Delhi, AIIMS New Delhi Jointly Establish Centre for Advanced Research and Excellence in Disability & Assistive Technology (CARE-DAT), a Centre of Excellence

Read More

IIT Delhi’s School of Artificial Intelligence to Start ‘M.Tech in Machine Intelligence & Data Science (MINDS)’

Read More

Applications are invited for appointment to the post of Director, Indian Institute of Technology (llT) Bhubaneswar

Read More

Advertisement inviting applications for the post of Director, IIT Palakkad, IIT Tirupati, IIT Dharwad, IIT Bhilai, IIT Goa and IIT Jammu

Read More

IIT Delhi to Teach School Students ‘How Powerful Computers Can Help in Providing Insights into Real-Life Phenomena’

Read More

IIT Delhi Announces Scholarships and Seed Funding Programs to Mark 2nd Anniversary of its Alumni Endowment Fund

Read More

IIT Delhi Launches New UG Programme ‘B. Tech. in Energy Engineering’; JEE (Advanced) Qualified Students Eligible

Read More

Alumnus Mohit Aron Gifts USD 1 Million to IIT Delhi’s Computer Science and Engineering Department

Read More

B.Tech. Students of NIT Sikkim to be Eligible for Direct Admission to IIT Delhi’s PhD Programmes

Read More

JK Paper Signs MoU with IIT Delhi to Set Up JK Paper Centre of Excellence in Paper and Packaging

Read More

IIT Delhi’s Over Rs 500 Cr State-of-the Art ‘Central Research Facility’ Now Open for Researchers from Across Country

Read More

Optics and Photonics Centre of IIT Delhi launches an outreach initiative named "Optics Learning Centre"

Read More

IIT Delhi Launches Sci-Tech Spins - A Series of Weekend Seminars & Laboratory Demos for High School Students

Read More

DAKSH Centre of Excellence (CoE) for Law & Technology, IIT Delhi Releases Report on Six High Court Websites

Read More

"ComIN21 Asian Voices in Pandemic" conference organized by the Department of Design, IIT Delhi in December 2021

Read More

Seminar on Benefits and Challenges in the Next Decade of Semiconductor Innovation by Dr. Randhir Thakur, Senior Vice President, Intel, USA on 19.08.2021 at 10:00 am

Read More

Unnat Bharat Abhiyan Announces Results of Regional Level Poster and Video Competition for COVID-19 Awareness

Read More

Vipula and Mahesh Chaturvedi Foundation Signs MoU to Attract Outstanding Talent to IIT Delhi

Read More

An Institute Lecture on "Ways to a Carbon-free world" by Mr. Sumant Sinha, Chairman and Managing Director, ReNew Power

Read More

National Health Authority and Indian Institute of Technology Delhi join hands to scale high-potential healthcare innovations

Read More

Attention 2020 Entry UG students: Final list of UG students (2020 Entry) for Change of Programme at the end of 1st Year

Read More

IIT Delhi Establishes Chairs to Support Research in Microelectronics & VLSI Design and Geotechnical & Geo-Environmental Engineering

Read More

IFFCO Signs MoU with IIT Delhi for Innovative & Collaborative Projects to Bring Labs to Farms

Read More

IIT Delhi Alumni Endow Indu Shrivastava & Serla Singh Chair Professor in Artificial Intelligence

Read More

Covid-19: What the pandemic has taught us and the way forward lecture by Prof./Dr. Randeep Guleria, Director, All India Institute of Medical Science (AIIMS), Delhi

Read More

IIT Delhi Establishes Manish Singhal Chair to Promote Teaching and Research in the Area of Smart Textiles

Read More

Supreme Court Judge Mr. Justice S. Ravindra Bhat inaugurates UJF Lab Facility on AI for Judiciary at IIT Delhi

Read More

PAID COVID VACCINATION CAMP - COVISHIELD - 8TH JUNE, 2021 (Tuesday), L.H.C., IIT CAMPUS - EMPLOYEES (FACULTY & STAFF)

Read More

IIT Delhi to Establish Department of Energy Science and Engineering: New UG Programme B.Tech. in Energy Engineering To Be Offered from This Year

Read MoreCovid-19: IIT Delhi collaborates with Delhi Government to improve oxygen infrastructure and supply chain management in Delhi

Read More

IIT Delhi to Create New Centre to Synergize and Boost R&D Activities in Optics and Photonics Field

Read More

_1731498114.jpg)

_1691059736.jpg)

_1651059243.png)