Publish Date: December 14, 2023

Rural Technology Action Group at IIT Delhi Transfers “AC Motor-Powered Wooden Bead Making Device” Fabrication Technology to Industry

Share this on

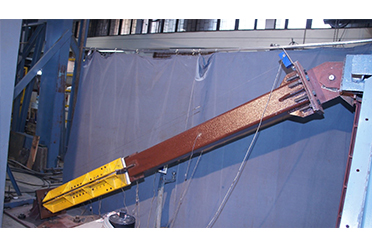

(Photo: AC Motor-Powered Wooden Bead Making Device)

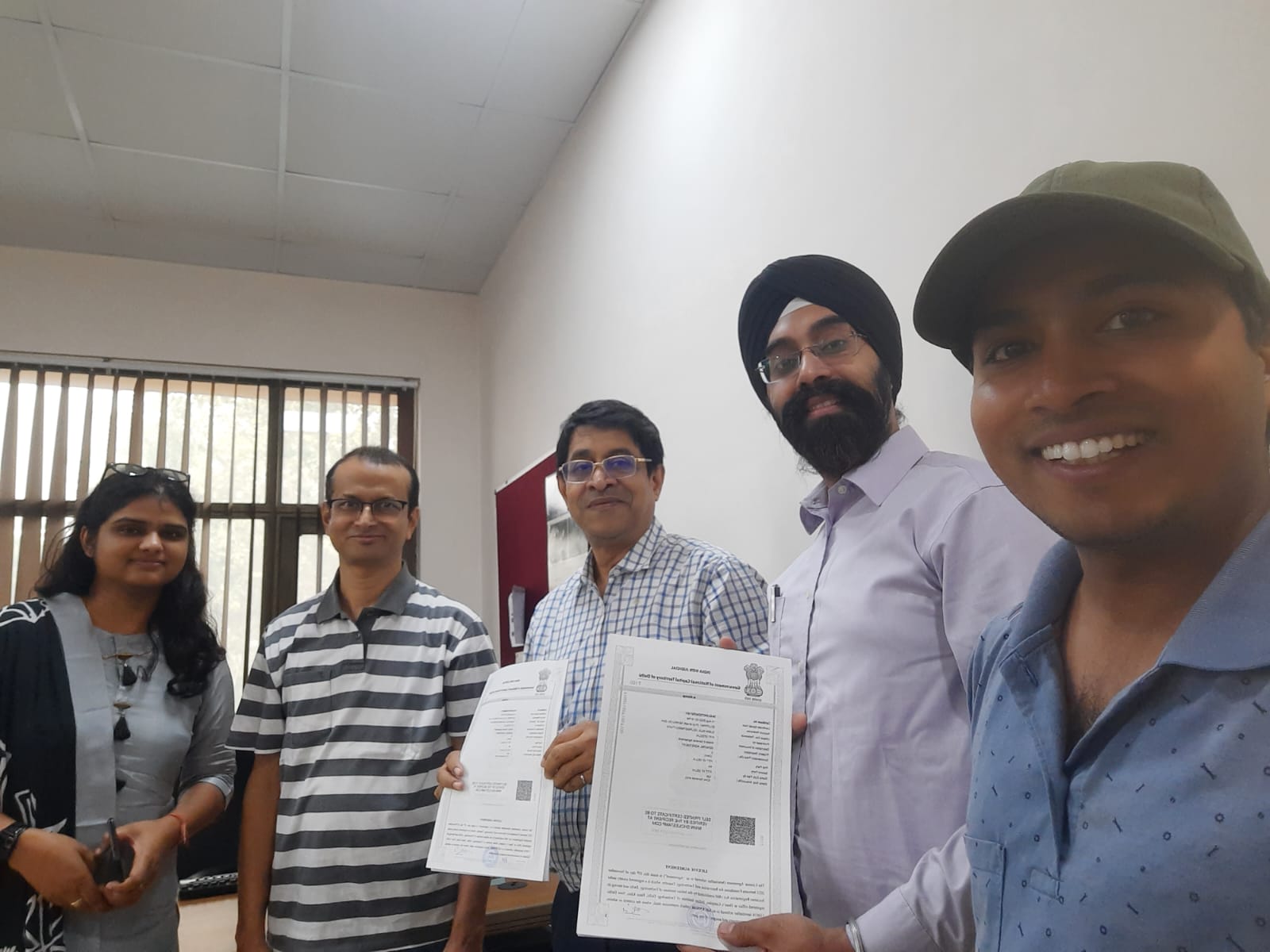

New Delhi: The Rural Technology Action Group (RuTAG) at IIT Delhi has transferred a technology to fabricate an AC motor-powered wooden bead-making device to the industry. The device will benefit the rural sector, particularly the women of Mathura, Vrindavan, and neighboring areas of Uttar Pradesh, India.

The technology has been licensed to Harraj Industries, which is planning to fabricate the device and sell it. The design of the device is protected under design registration in the Indian Patent Office. The technology was transferred through FITT-IIT Delhi.

“The AC Motor-Powered Wooden Bead Making Device has evolved over a decade as a science and technology project due to the constant efforts of the RuTAG IIT Delhi team that worked hard to improve the ergonomics and reduce the drudgery of the women artisans,” said Prof. SK Saha, Project PI and professor at IIT Delhi.

The third and latest version of the device proposed by an IIT Delhi PhD student, Mr. Yashwant Prasad, is almost noiseless. It has also enhanced the daily productions and earnings of the artisans to about Rs. 3000 per day from Rs. 700–800 per day.

"We plan to sell the device through GEM (Govt. E-Marketplace) and other e-commerce platforms so that exporters and other interested customers located in any corner of the country can easily procure it," said Mr. Harpreet Singh, Proprietor, Harraj Industries.

The device can make spherical beads from 5 mm to 25 mm in diameter from wood. It performs turning and drilling operations simultaneously, while the operational speed can vary between 2000 and 3000 rpm using an advanced speed control (variable frequency drive). Presently, these beads are mainly made from Tulsi (Holy Basil) stems to make garlands for devotees.

Photo 1: MoU Signing Ceremony for Technology Transfer (From Left to Right- Prof. Preeti Ranjan Panda, MD, FITT; Prof. S. K. Saha; Mr. Harpeet Singh, PhD Student Yashwant Prasad)

(Photo 2- Wooden beads)

ENDS