Publish Date: April 26, 2022

Researchers Led by IIT Delhi Develop Technology to Enable Use of Environment-Friendly Dimethyl Ether as Fuel in Automotive Vehicles

Share this on

Technology Developed by Researchers from IIT Delhi, IndianOil (R&D), Ashok Leyland with DST’s Fund Support

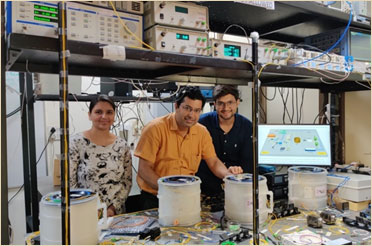

Photo 1: Flagging Off of DME-Diesel DOST Vehicle at IIT Delhi

New Delhi: Researchers from the IIT Delhi’s Department of Energy Science and Engineering (DESE), Indian Oil Corporation (IOC R&D), and Ashok Leyland Ltd. have developed a technology, which enables a diesel-powered automotive vehicle to run in flex fuel mode i.e. either 100% diesel or Dimethyl Ether (DME) plus Diesel mode. The project was funded by the Department of Science and Technology (DST), Government of India.

Using this technology, the researchers converted a diesel-powered automotive vehicle into a flex fuel vehicle on a pilot basis. This flex fuel technology-based vehicle DOST was jointly flagged off on 8th April 2022 at IIT Delhi by Dr. Srivari Chandrasekhar, Secretary, DST; Prof. Rangan Banejee, Director, IIT Delhi; Dr. SSV Ramakumar, Director (R&D), IndianOil; Shri. Krishnan Sadagopan, Senior Vice President, Ashok Leyland; Prof. Sunil Kumar Khare, Dean R&D, IIT Delhi; Prof. K. A. Subramanian, Head, DESE, IIT Delhi in the presence of senior officials from IIT Delhi, IOC R&D, and auto major Ashok Leyland.

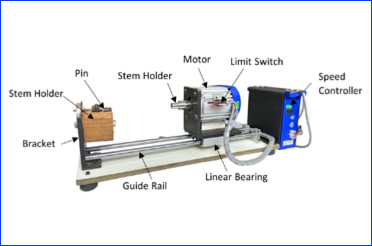

The flex fuel engine technology for use of DME is developed by IIT Delhi, and IOC R&D undertook the endurance and field trials tests and developed the dedicated engine oil with the technical support of Ashok Leyland.

Dimethyl Ether (DME) is one of the alternative fuels to compression ignition engines/vehicles as it has a higher cetane number (~58) than that of conventional diesel (51). DME can be produced from Biomass, Coal, Industrial Wastes, Municipal Solid wastes, Black liquor (a by-product of pulp) through gasification and the Fisher-Tropsch synthesis process. It can also be produced via catalytic dehydration of methanol. DME is generally stored in liquid and phase change from liquid to vapor/gas could easily occur at the ambient temperature and pressure.

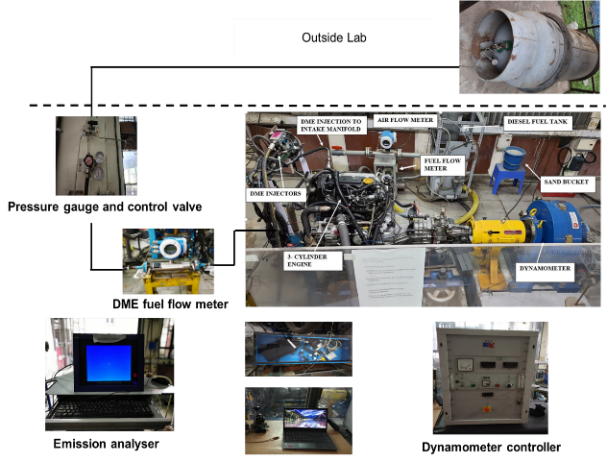

Speaking about the flex-fuel automotive vehicle technology, Prof K. Subramanian, Head, Department of Energy Science and Engineering, IIT Delhi said, “DME fuel is injected into the intake manifold of the engine, and diesel is directly injected into the engine cylinder. The CRDI system controls both diesel and DME fuel injection with respect to the load. The engine/vehicle operates with the optimum DME energy share without a knock.”

Key highlights of the technology developed by IIT Delhi, IOC R&D, and Ashok Leyland:

- Flex Fuel Vehicle Technology (Vehicle can run both modes: either 100% diesel or DME-Diesel mode)

- The transition of diesel trucks from conventional diesel to DME as an alternative fuel (First phase as Flex Fuel Vehicle; Second Phase as dedicated 100% DME/alternative fuelled vehicle)

- Less / negligible smoke/soot/PM emission

- Lower noise with smoother engine/vehicle operation

- Improvement in transient engine performance

- Enhancement of energy security

- Sustainable environment as there is substantial reduction in Greenhouse Gas Emission

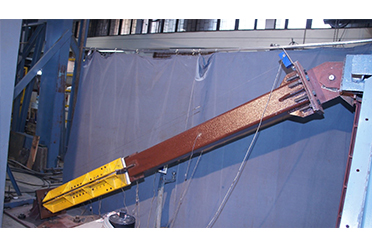

Photo 2: Developed Research Test Set-up at Department of Energy Science and Engineering (DESE), IIT Delhi

Photo 3: DME fuel being filled in Dost Vehicle by Portable dispensing system at IOC (R&D)

**********